Umatshini wokuzalisa isiselo esizenzekelayo se-carbonated

Buza Ngokuumatshini wokuzalisa isiselo se-carbonated-Iimpawu

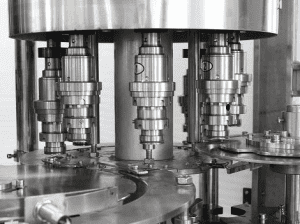

1. Olu hlobo lomatshini wokuzalisa isiselo se-carbonated ludibanisa ukuhlamba, ukuzalisa kunye nemisebenzi ye-rotary capping kwiyunithi enye.Isixhobo sokupakisha samanzi ngokuzenzekelayo ngokuzenzekelayo kwaye siphezulu.

2. Umatshini wokuzalisa isiselo se-carbonated ufanelekile ukupakisha isiselo esinegesi. Ukusebenza komatshini wokuzalisa isiselo se-carbonated kunjengokulandela zonke iindawo, umzekelo, ivalve yokuzalisa, enxibelelana ngokuthe ngqo nesixhobo esenziwe ngentsimbi engenasici okanye izinto ezingenabungozi. Ngoko ke ihambelana neemfuno zococeko lokutya. Iindawo zokutywina zenziwe ngerabha ekhusela ubushushu, ukuze kuhlangatyezwane neemfuno zobugcisa zabasebenzisi ukwenza inzala kwiqondo lobushushu eliphezulu.

3. Umatshini wokuzalisa isiselo se-carbonated usebenzisa isilawuli esicwangcisiweyo ukuqonda ngokupheleleyo ulawulo oluzenzekelayo ukusuka kwiibhotile ezingenayo ukugqiba ukupakisha, umatshini wokuzalisa isiselo se-carbonated usebenzisa i-transducer njengomlawuli wesantya, ngoko ke umsebenzisi unokulawula umatshini ngokulula ukuze ahambelane neemfuno zamandla ahlukeneyo, Ukwamkela umgaqo wokuzalisa uxinzelelo olulinganayo. kunye neevalvu zasentwasahlobo zangoku ukuze kuqinisekiswe umgangatho wesiselo, Ukusebenzisa i-coupler yamagnetic ehambele phambili yokulawula i-torque ye-cap-screwing, ukuze kuqinisekiswe i-capping. umgangatho.

Ipharamitha yobugcisa

| Umzekelo | DCGF 16-12-6 | DCGF 18-18-6 | DCGF 24-24-8 | DCGF 32-32-10 | DCGF 40-40-12 | DCGF 50-50-15 |

| Ukuhlamba inombolo | 16 | 18 | 24 | 32 | 40 | 50 |

| Ukuzalisa inombolo | 12 | 18 | 24 | 32 | 40 | 50 |

| I-Capping No | 6 | 6 | 8 | 10 | 12 | 15 |

| Umthamo wemveliso(500ml) | 3000BPH | 5000BPH | 8000BPH | 12000 BPH | 15000 BPH | 18000 BPH |

| Faka isakhono(KW) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Ubungakanani bubonke | 2450×1800 × 2400 | 2650×1900 × 2400 | 2900×2100 × 2400 | 4100×2400 × 2400 | 4550×2650 × 2400 | 5450×3210 × 2400 |

1. Ukusebenzisa umoya wathumela ukufikelela kunye nokuhambisa ivili kwibhotile eqhagamshelwe ngokuthe ngqo ubuchwepheshe; Screw kunye namatyathanga okuhambisa, oku kwenza ukuba utshintsho olumilise ibhotile lube lula.

2. Ukuhanjiswa kweebhotile kwamkela itekhnoloji ye-clip bottleneck, inguqu eyenziwe yibhotile ayifuni kulungelelanisa inqanaba lesixhobo, utshintsho olunxulumene nepleyiti egobileyo, ivili kunye neendawo zenayiloni zanele..

3. Ikliphu yomatshini wokuhlamba ibhotile eyenzelwe ngokukodwa insimbi engenasici iqinile kwaye iqinile, akukho nto idibanisa ne-screw indawo yomlomo webhotile ukuphepha ukungcola okwesibini.

4. I-cylinder drive ivalve iintshukumo zichanekile kwaye zithembekile. I-valve yokuzalisa i-high-throughput, i-high-precision-precision filling valve, ukuzaliswa ngokukhawuleza nangokuchanekileyo. Ixhotywe i-loop ye-CIP kunye neenkqubo zokulawula, izixhobo zilula ukuzicoca.

5. Ukwehla kwe-Spiraling xa ibhotile yemveliso, guqula imilo yebhotile akukho mfuneko yokulungelelanisa ukuphakama kwamakhonkco okuhambisa.

6. Ukusebenzisa isilawuli esicwangcisiweyo njengamaziko olawulo; usebenzisa isidluliseli soxinzelelo, umlinganiso we-electromagnetic ukugcina ulungelelwaniso lomphezulu wolwelo ukuze kuqinisekiswe uzinzo lolwelo.

7. I-valve entsha yokuzalisa ukuyila, igesi yokubuyisela kunye nokuzalisa ulwelo lwahlukileyo ukuze kuqinisekiswe ukuba izinto zokuzalisa zicocekile.

8. Umatshini wamkela isivalo se-screw clutch esiphezulu kunye ne-torque ye-torsion iyahlengahlengiswa, ngoko ke i-screwing ikhuselekile kwaye ithembekile.

Iimveliso ezicetyiswayo

Ngakumbi +- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur